In a nutshell: TSMC is venturing into uncharted territory with a novel method to superior chip packaging. The chipmaker reportedly plans to change from typical spherical wafers to rectangular substrates, permitting considerably extra chips to be positioned on every wafer.

The proposed rectangular substrate is presently present process trials. Measuring a considerable 510mm by 515mm, it reportedly boasts over 3 times the usable space of present spherical wafers. Moreover, the oblong form reduces wasted area across the edges. The examine continues to be within the early levels, and its outcomes could take a number of years to succeed in the market.

Traditionally, substrates have been spherical on account of their dealing with benefits and superior energy. Nevertheless, the sudden curiosity in altering this development is unsurprising given the AI growth. Like different chipmakers, TSMC is feeling the stress from the skyrocketing demand for computing energy and goals to maintain tempo.

It is fascinating to see how chip packaging, as soon as thought-about the much less glamorous aspect of chipmaking, has change into essential in advancing semiconductor know-how.

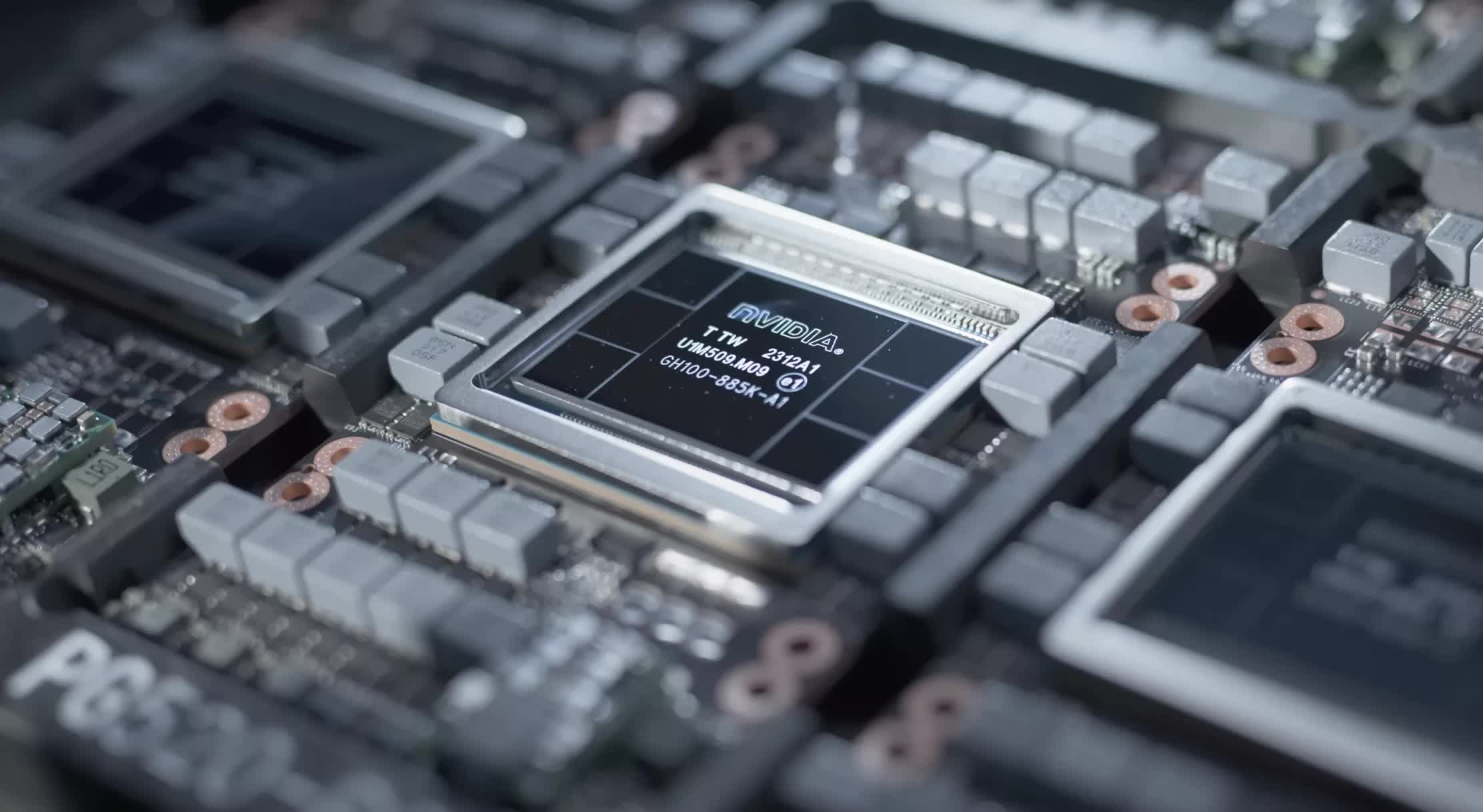

As an example, Nvidia’s H200 and B200 AI computing chips depend on TSMC’s state-of-the-art CoWoS (chip-on-wafer-on-substrate) know-how. This superior packaging methodology combines a number of processing items and high-bandwidth recollections, leading to quicker knowledge throughput and improved computing efficiency.

As chips develop bigger to accommodate extra transistors and reminiscence, the present 12-inch wafer normal may not suffice in a few years. That is the place TSMC’s rectangular substrate experiment is available in.

Nevertheless, this shift will not be a stroll within the park. TSMC and its suppliers might want to make investments important time and sources into improvement. They will additionally need to improve or exchange a considerable quantity of manufacturing instruments and supplies. One main hurdle is determining apply photoresists (light-sensitive supplies utilized in chip manufacturing) on these new rectangular substrates, a chip govt instructed Nikkei Asia.

TSMC will not be the one producer experimenting with cutting-edge substrate applied sciences. Its greatest competitor, Samsung, is rumored to be investing closely in analysis and improvement of glass substrates for chip manufacturing, with the aim of bringing merchandise to market as early as 2026. Utilizing glass presents a number of benefits in comparison with natural substrates, corresponding to enhanced flatness, which improves the depth of focus for lithographic processes.